Nature’s Edge Industrial

Cleaner, Vapor Suppressant & Bio-Treatment Product Profile Non-Toxic * Non-Hazardous * Biodegradable * Mild pH

Developed for the petrochemical and other heavy industries for general cleaning/ degreasing, eliminating hydrocarbon contamination in concrete, soil and water and reducing vapors on contact i.e. VOC’s/ LEL’s, H2S, SO2, etc. A unique multi-functional aqueous based non-toxic concentrate with oil-digesting microbes, Nature’s Edge Industrial reduces risks, costs and liabilities associated with cleaning, transfer, storage and disposal of hydrocarbons. Nature’s Edge Industrial breaks down and encapsulates hydrocarbons with minimal agitation, significantly reducing time and labor required to gain entry to towers/tanks and minimizing water usage and disposal. Nature’s Edge Industrial is low foaming, has no adverse effect on water systems and has a pleasant scent, leaving the area deodorized and surfaces free of oily residues after rinsing.

Nature’s Edge Industrial is an effective replacement for caustic and other harsh chemicals for degreasing, plus offers important benefits not typically associated with degreasers. A few of the many side benefits of use include enhancing separation of solids and oils to extend filter life, deodorizing and controlling foul odors, reducing sludge build-up in drains/ lines, separators and restoring unsightly areas around pumps, compressors and bulk storage areas. Additionally, benzene and other unwanted BTEX are targeted for digestion by the microbes (added during manufacture), biologically reducing hazardous classification of wastes in many cases.

Having passed the LC-50 toxicity test and HOCNF test for discharge in the North Sea, Nature’s Edge Industrial is safe for use in areas where aquatic or wildlife could be affected. Nature’s Edge Industrial is particularly useful for NGL processing/ terminal operations, fueling stations, bulk storage areas, loading docks, rail yards, closed environments such as tunnels and wherever environmental, occupational, health and safety issues are of great concern. May be applied using pumps, pressure washers, mops, sprayers, etc. It is non-irritating to normal skin and will not harm equipment internals.

Product# 250. Concentrate has a 2 year shelf life. Packaged in 5 gal pails, 55 gal drums and 275/330 gal totes. DOT Shipping Class 55. Non-hazardous.

Special Features:

High performing, safe, heavy duty cleaner/ degreaser

Reduces vapors on contact – VOC’s/ LEL’s on contact

Biologically eliminates hydrocarbon contaminants in water, soil and concrete

Biodegradable, non-toxic, non-hazardous, non-corrosive, no adverse effect on water systems

Contains safe, all-natural, non-pathogenic, select oil digesting microbes

Mild pleasant scent – no obnoxious or pungent citrus fumes; Controls foul odors

Typical Uses:

Cleaning/ degreasing/deodorizing floors, concrete, equipment, machinery, hoses, tools, etc.

Maintaining appearance around pumps, compressors, sample points

Reducing hazardous classification of wastes/waste water discharge and liabilities

Clearing vessels/tanks for entry/maintenance

Reduce oil and sludge build-up and foul odors in separators and sumps

Oil spill clean-up

Vapor Control

LNG/Gas Operations

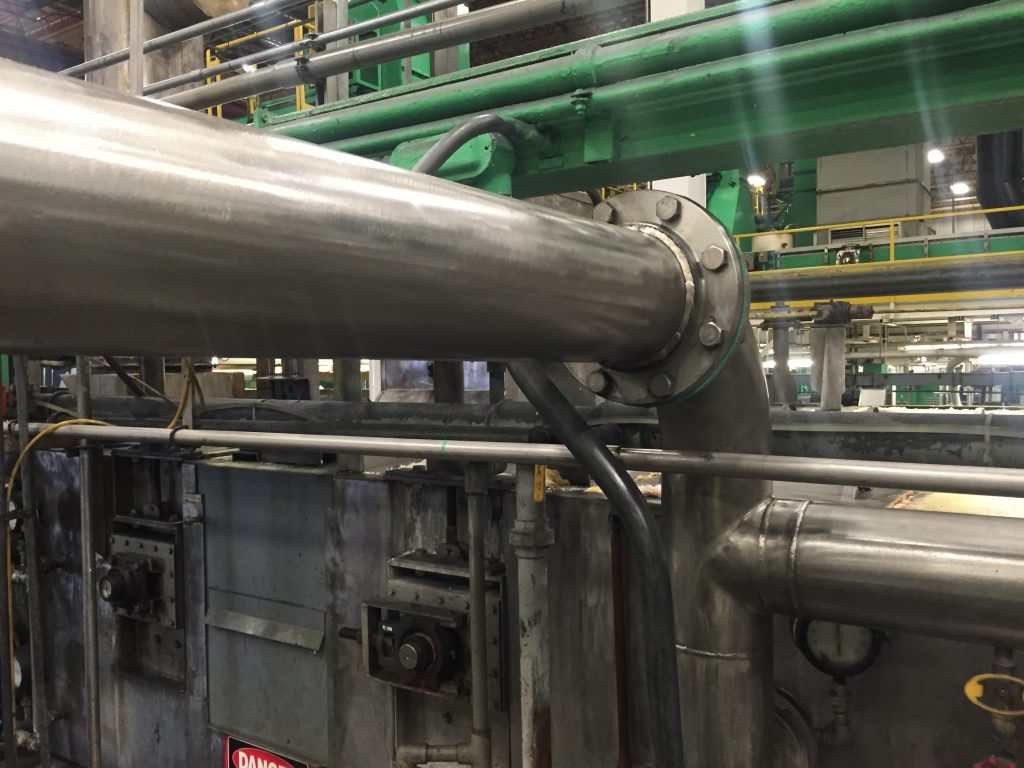

Pre-filters/filter pots, Coalescers, Caustic Towers, and Associated Lines

Pre-filters/filter pots, Coalescers, Caustic Towers, and associated lines were cleared of LEL’s, and H2S using Natures Edge Industrial (NEI); Additionally, NEI along with Gold Edge (GE) were used as a system to simultaneously knock out Benzene (NE), liquefy heavy sludge (GE) for NEI’s consuming microbes, while eliminating the need for a chemical cleaning/circulating contractor. Unit operations established new SOP’s as well as engineering modifications to equipment to allow for a larger volume of the chemistry to circulate through the vessels, saving multiple down-days, reducing overall cost and performing the task with in house maintenance and operations personnel. Environmental Edge Tech’s field operations consultants were instrumental in working hand in hand with customer operations folks on a 9,000 gallon coalesce with an amines dropout tank as a successful pilot test.

LEL/VOC Elimination

Nature’s Edge Industrial

Cleaner, Vapor Suppressant & Bio-Treatment

An aqueous concentrate that reduces VOC’s/ LEL’s on contact, including H2S, SO2, pygas, mercaptans and other hydrocarbons. Also penetrates and releases layers of solid build-up while inhibiting re-adherence in lines and tanks downstream. Increases profitability, productivity and safety in production and transportation of natural gas and hydrocarbon liquids.

Hydrocarbon Vapor Neutralizer

Crude Lines at Docking Facility

Houston Area Port Facility

NEI (Natures Edge Industrial) and GE(Gold Edge) were used to clear approximately 2000 feet of varied size crude oil piping prior to removal from a refinery loading dock. Piping had never been cleared/cleaned due to the location, daily use requirements and limitations of size and design in at least 35 years according to plant personnel. Environmental Edge field operations consultants assisted plant operations and maintenance personnel in planning and initiating the clearing project. Originally requesting 4 days to complete the degassing and clearing project, we were given only 2 days. With proper application and established protocol, it was accomplished in 2 days. When the line was all clear and cut for removal, the facility Ops Manager said “smells like the Caribbean”. The entire dock was removed and the replacement dock was literally floating up the Houston Ship Channel as the old one was floating down.

Benzene Remediation

Natures Edge Industrial

Natures Edge Industrial (NEI) is engineered to reduce VOC’s, LEL’s, H2S, SO2, Benzene, vapors and gases on contact eliminating the need for multiple water fills, steam/chemical circulating and even thermal oxidizer (TO) units; also is a wetting agent/penetrant that inhibits adherence and build-up of sticky residues and solids. NEI is a non-hazardous, aqueous based, multi-functional Industrial concentrate with oil consuming microbes.

Gold Edge (GE), Gold Edge X40 (X40)

GE is a non-petroleum based solvent that is non-toxic, flash point above 400f degrees PMCC and will dissolve asphalt at ambient temperature. X40 is GE with select additives allowing X40 to break down and dissolve paraffin based hydrocarbons and many polymer/plasticizer materials. According to the scope of work, a protocol can be prepared whereby the products are used separately or together as a system.